Diaphragm pumps, in agriculture, are essential tools for different stages of cultivation, used in every spray boom system or sprayers.

In this article, therefore, we will find out about the features, operation, benefits, how to maintain and fix malfunctions of diaphragm pumps, so that you can choose the most suitable one for your farming operation.

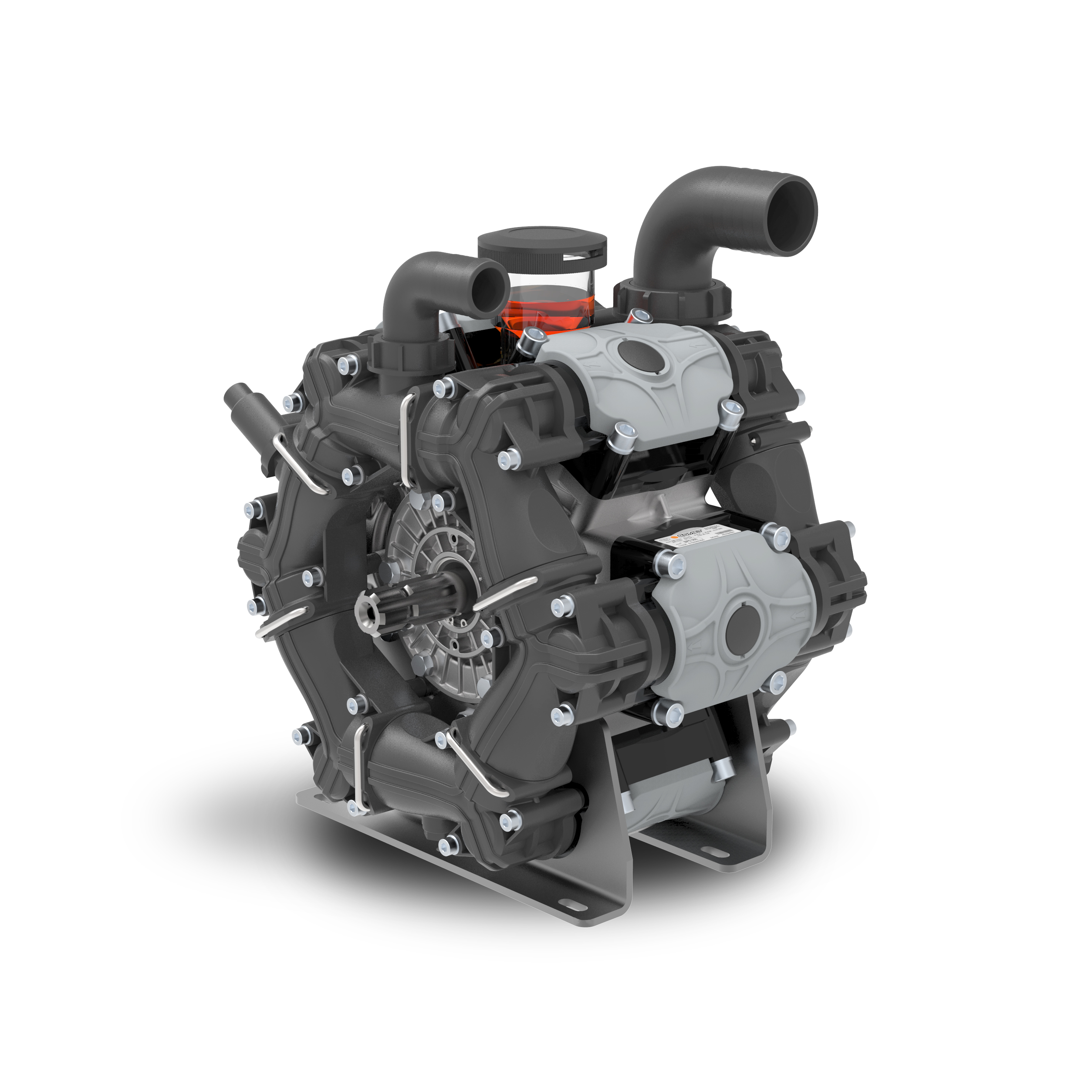

WHAT A DIAPHRAGM PUMP LOOKS LIKE

The diaphragm pumps are ideal for spraying and weeding treatments of agricultural crops such as cereals, vegetables, orchards, vineyards and olive groves.

In fact, among the main benefits of their use in agriculture are excellent priming and self-priming, good dry-running and mechanical-chemical resistance to chemicals.

The main feature that distinguishes the diaphragm pump from other types of volumetric reciprocating pumps is that it has an elastic separating element between the mechanical components and the processed liquid circuit, keeping the pumping chamber and transmission separate, thus preventing the fluid from coming into contact with the mechanical components and the oil, causing serious damage to the pump.

Let’s use a “home-made” example to help us: we can compare the diaphragm pump to an injection syringe. In an agricultural pump, therefore, the diaphragm consists of a rubber disk screwed onto the piston. Exactly as in the syringe, during the suction phase, the pump sucks in a liquid due to the vacuum created inside the pumping chamber, compensates for the pressure imbalance by means of the principle of communicating vessels and sucks the liquid back to the lower pressure space. In the subsequent delivery phase, on the other hand, the pressure increase inside the pumping chamber pushes the liquid outwards. The two phases together make up a complete pumping cycle.

Expansion and contraction are generated by means of the alternating oscillations of an elastic element, called the diaphragm. Since the chamber has a defined and invariable maximum volume, the volume pumped in each cycle is constant, regardless of pressure. For this reason, positive displacement pumps are called volumetric or constant flow pumps.

LEARN MORE: THE COMPONENTS OF THE DIAPHRAGM PUMPS

PERFORMANCE OF A DIAPHRAGM PUMP

Whatever the liquid to be pumped and whatever the use of this liquid, the purpose for which a diaphragm pump is employed is to lift a liquid from a lower to a higher point.

There are several parameters, however, that make up the difference in performance between one pump and another, and for use in agriculture - e.g., for sprayers - particular attention should be paid to pump pressure and flow rate, two factors that relate to power. Once established the pressure and flow rate we need, we can track the power needed to drive our pump.

We are talking about performance parameters closely related to physics concepts as varied as they are numerous, namely:

- Flow rate

- Head

- Pressure

- Power

- Speed

- Pressure drop

- Output

- Positive net suction head

Each pump, therefore, has several of the listed parameters, each of which is indicated on the appropriate data sheets of the individual pump models available on the market.

LEARN MORE: THE MAIN PARAMETERS DEFINING THE PERFORMANCE OF A PUMP

HOW TO CHOOSE A DIAPHRAGM PUMP FOR THE SPRAYER

In order to properly choose a diaphragm pump, especially for a sprayer, the parameters listed above should be well taken into account, in addition to the type of treatment to be carried out.

For example, the pressure of a sprayer ranges from 30 to 40 bar, so pumps resistant to these pressures should be chosen. Spraying pesticides for vineyards, olive groves, or orchards, on the other hand, involves high mechanical abrasiveness because of the crystals that make up, e.g., copper sulfate: similarly, therefore, pumps made of brass or anodized aluminum should be chosen. Finally, for heavy-duty pumps, such as those for rear turbines, you should opt for pumps with high power and sturdiness.

LEARN MORE: HOW TO CHOOSE THE RIGHT DIAPHRAGM PUMP FOR YOUR SPRAYER

MAINTAINANCE OF A DIAPHRAGM PUMP

Proper maintenance of a diaphragm pump can help you extend the life of your sprayer or spray boom system. In fact, with each use, it is a good idea to inspect the pump before startup, thus checking the hydraulic system for signs of wear and clogging to avoid failure or low performance.

DISCOVER COMET’S RANGE OF DIAPHRAGM PUMPS FOR AGRICULTURE

Routine maintenance tasks, to be carried out after 300 hours of operation or at the end of the season, include draining and flushing the pump and installing a new set of diaphragms.

The oil change is equally important, since perfect lubrication helps the operation of the individual components of the pump and increases its overall performance. For this reason, it is essential to always keep an eye on the oil level and check its condition.

A general recommendation is to rely on genuine spare parts and have special kits available consisting of diaphragms, valves and gaskets.

LEARN MORE: MAINTENANCE OF A DIAPHRAGM PUMP, THE RIGHT OIL EXTENDS ITS LIFE

TROUBLESHOOTING A DIAPHRAGM PUMP

Often, unfortunately, proper maintenance is not enough to prevent a diaphragm pump from experiencing problems, such as failure to load water or lack of pressure.

To avoid having to stop your work because of a sudden failure and to prevent unexpected malfunction, you need to recognize the signals your pump may give you, such as unusual noises or vibrations.

To help you, we have summarized in a special article the most common problems that can occur during normal use of a diaphragm pump and the actions needed to solve them.

LEARN MORE: TROUBLESHOOTING A DIAPHRAGM PUMP