The purpose of a hydraulic pump is to lift a liquid to a higher level than the starting one; therefore, when we choose a pump we must first of all take two things into consideration: the volume of the fluid that we must move and the height at which it must be lifted. The parameters corresponding to this information are flow rate and head.

Parameters for agricultural pumps

As far as agricultural pumps are concerned, such as those mounted on sprayers, in addition to flow rate we will also have to pay close attention to pressure: in spraying and plant protection treatments, in fact, the liquid output pressure directly affects the effectiveness of the treatment itself.

Flow rate and pressure are closely related to power. Once the pressure and flow rate we need have been set, we can also find the power required by our pump.

On the website and in the catalogues of Comet pumps for agriculture, you will find a diagram for each pump model indicating Pressure, Flow Rate, Power and Speed.

In the following paragraphs we will describe the parameters that we have seen so far:

Along with other important pump efficiency parameters:Flow rate or pumped volume

The flow rate (Q) is the volume of fluid moved in the unit of time. The flow rate is normally expressed in:

- m3/s (cubic metres per second)

- l/min (litres per minute)

- gpm (gallon per minute)

In the case of pumps, the flow rate consists in the quantity of fluid that flows from the pump delivery in the unit of time, also called the pumped volume.

Head

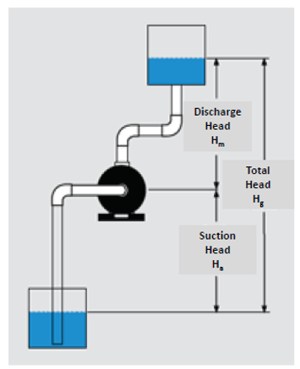

Head (H) is the ability of a pump to lift a certain volume of liquid to a given height. In other words, it is the maximum lifting height difference.

In the SI metric system, it is measured in meters water column (m W.C.) or more simply in meters.

To define the head H, which is required to push a certain volume over a certain height difference, it is necessary to add two variables:

Head H = Hg+Y

Hg = the geodetic head, i.e. the difference between the liquid level in the delivery tank and in the suction one.

Hg = Ha+Hm

Ha = geodetic suction height and represents the difference in level between the axis of the pump and the surface of the liquid to be sucked. It has a positive value if the liquid level is above the pump axis, it has a negative value if the liquid level is below the pump axis, as in the image.

Hm = geodetic delivery height, i.e. the difference between the axis of the pump and the liquid level in the basin from which the liquid is pumped.

Y represents the loss of head due to the losses of energy caused by the friction of the liquid and by the presence of narrowing, curves, etc.. (see also pressure drop). The performance of the pump must be able to compensate for these losses in order to achieve the required lifting.

Head, like pressure, measures the kinetic energy transferred from the pump to the liquid, but unlike pressure, it is based on volume, so it is independent of the specific weight of the pumped fluid. Therefore, the head of a pump is the same, regardless of the specific weight of the fluid being pumped.

Pressure

Pressure (p) is the ratio of a force (F) acting orthogonally (perpendicularly) on a surface to its area (S).

The pressure is normally expressed in:

- pascal = 1N/m² (1 Newton per square metre)

- bar = 100 kPa (100 kilopascal)

- atm (atmosphere) = 1,01325 bar = pressure exerted by the earth's atmosphere at sea level. It is usually approximated to 1 bar.

- psi (Pounds per Square Inch) or pound strength per square inch.

Head and pressure of a pump are related parameters.

Head - pressure conversion formulas in the metric system:

From head (in meters) to pressure (in bar)

p = 0.0981 h · SG

where:

h = prevalence (m)

p = pressure (bar)

SG = specific weight

From pressure (in bar) to head (in meters)

h = p · 10.197 / SG

where:

h = head (m)

p = pressure (bar)

SG = specific weight

In the case of pumps, pressure is the force given by the machine to the pumped fluid, i.e. the propulsive thrust with which the fluid exits the pump.

Like the head, the pressure delivered by a pump can also be subject to dispersions, called pressure drops, which must be taken into account in the construction of the circuit.

Pressure drop

The pressure drop between two points in a hydraulic circuit is the difference in hydraulic load between the two points considered.

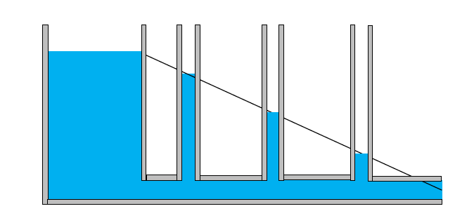

Let's consider, for example, a basin where a free surface fluid is at a certain height, connected to a duct. Gravity tends to cause the fluid to flow downwards and out of the duct. During its motion, the fluid loses energy, as can be seen from the different and decreasing heights reached by the liquid in the subsequent communicating vessels.

These energy losses are caused by resistances to the free flow of the fluid, generated by a number of factors, such as:

- speed, viscosity and temperature of the fluid

- diameter, length and roughness of the pipes used

- presence of obstacles on the circuit, such as valves, taps, curves

The formulas for calculating the pressure drops are quite complex, so we recommend using online automatic calculators, such as: Pressure-Drop-Online-Calculator

Power

In physics, power (P) is the energy transferred, produced or used by a physical system in the unit of time.

It is measured in

- watt (W) = ratio of unit of energy in joules (J) to unit of time in seconds (s):

- CV (European horse power DIN) = 735.49875 W

- HP (British horse power) = 745.69987158227022 W

CV and HP are actually equivalent: 1 CV = 0.98631 HP

In our context, power is the amount of energy that must be transferred to the pump to lift a given flow rate Q to a given height H, in the unit of time.

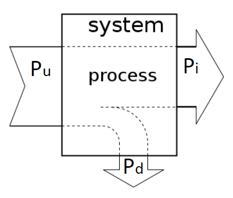

To calculate the power generated by a pump, two factors must be taken into account: useful power (Pu) which is the amount of energy available, i.e. the energy transferred from the motor to the pump and dissipated power (Pd), i.e. the energy lost by the pump due to mechanical and hydraulic causes.

The difference between useful power and dissipated power determines the hydraulic power (Pi), i.e. the amount of energy actually transferred from the pump to the fluid.

Pi = Pu - Pd

Efficiency

The useful power of any circuit must always be above the hydraulic power. In other words, the selected motor must have higher power than that intended to be applied to the fluid, in order to compensate for the dissipation.

The ratio of hydraulic power to useful power is called efficiency (η - eta).

η = Pi/Pu

Efficiency is the ability of the pump to transform mechanical energy into hydraulic energy (efficiency).

For the above reasons, its value is always lower than the unit. The closer it gets to 1, the more efficient the pump is.

NPSH (net positive suction head)

The net positive suction head consists in the difference between the pressure existing in a fluid at a certain point of a hydraulic circuit and the required pressure for that fluid to pass into the gaseous state at that same point, called the vapour pressure.

In practice, the NPSH is used to define minimum pressure and head, below which cavitation is created when sucking.

The NPSH is distinguished into:

1. NPSH(a) - Net Positive Suction Head available:i.e. the net head actually available on the circuit. The value is closely related to the characteristics of the plant, so it must be calculated from time to time, through a specific formula:

NPSH (a) = pa + Ha - pF - pVP

Where:

- pA = absolute pressure on the surface of the fluid in the suction basin.

Typically this is atmospheric pressure, so = 101 325 Pa = 1.01325 bar = 14,696 psi. - Ha = geodetic suction height, i.e. the distance between the fluid level and the axis of the pump. As already seen, its value is positive if the level is above the pump axis, while it is negative if the level is below the pump axis.

- pF = pressure drop due to pipes and fittings acting as restrictions against the flow of the fluid

- pVp = vapour pressure of the fluid at the pumping temperature.

It should be remembered that the vapour pressure increases as the temperature rises. The calculation can be carried out either in units of length (to obtain head) or in units of pressure.

2. NPSH (r) - Net Positive Suction Head required, i.e. the minimum suction head (pressure) required by the pump, the value of which is supplied by the pump manufacturer.

It is essential that: NPSH (a) > NPSH (r)

In other words, head, and therefore the available pressure on the circuit suction must always be above the minimum values required by the pump.

Therefore, when creating the circuit, it is essential to check if the pressure measured on the pump suction is higher than that indicated by the performance data of the pump itself. This will drastically reduce the risks of cavitation.

Speed

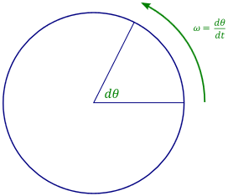

The angular speed ω(t), also called rotational speed, consists in the variation of the measure of an angle (Δθ), over time (Δt). [ω = omega; Δ = delta; θ = theta]

-

Angular speed is measured in rpm (rounds per minute), i.e. the number of complete revolutions (360° complete angle) made in one minute.

The (angular) speed of a pump is used to determine:

- the rotational speed of the drive shaft

- the rotational speed of the impeller, in the case of a centrifugal pump.