The proper operation of a diaphragm pump often depends on its proper installation and careful maintenance.

However, even a properly installed pump can sometimes have problems, such as priming, pressure, pulsation, noise or oil consumption problems. If you feel that the pump is not performing as it should, you must take immediate action to understand the cause of malfunctioning and restore it.

In this article we have summarized the most common problems that may occur during the normal use of a diaphragm pump and the necessary actions to fix them.

Some procedures are routine maintenance, while others should be carried out by skilled technicians or at authorized service centers.

Problem, cause and remedy of the main malfunctions of a diaphragm pump:

Pump does not prime or does not draw water

When the pump does not prime or draw water, there are generally three causes:

- The control regulator is in "pressure"

Don't panic, before starting to dismantle your pump always check that the control regulator is in "by-pass" mode, this problem is very often due to inattention. - Problems on the suction line, i.e. pipes or fittings are sucking in air. The entire suction line must then be inspected and it must be ensured that pipes and fittings are securely fastened.

- Clogged suction filter, if the suction line is intact and functioning, you must remove the suction filter and clean it if it is clogged.

No pressure or lower pressure than necessary

Pressure problems may be caused by an RPM speed that is not adequate to the technical characteristics of the pump, in this case it is sufficient to reset the number of revolutions indicated in the manual to recreate the pressure necessary for a correct use.

Pressure problems may be caused by an RPM speed that is not adequate to the technical characteristics of the pump, in this case it is sufficient to reset the number of revolutions indicated in the manual to recreate the pressure necessary for a correct use.

If the pressure continues to remain low or equal to zero, the problem may probably concern the nozzles; if the nozzles are worn or with a flow rate exceeding that which can be reached by the pump, they must be replaced.

Irregular pressure

- First check the suction line, if pipes or fittings are sucking air the pressure inside the pump is obviously affected.

- The pulsation dampener may be set incorrectly. The dampener absorbs vibrations generated by the oscillating movement of the diaphragms thanks to a pressure chamber. If not set correctly, the dampener pressure can affect the pump pressure. Simply restore the correct pressure inside the dampener and the pump pressure will be regular again.

- Another cause may be the incorrect configuration of the pressure regulator, check the pressure setting of the regulator (and if necessary, repair or replace it).

Excessive pulsations

In the event of excessive pulsations or vibrations, you should certainly check the pulsation dampener, as the purpose of this instrument is to reduce pulsations. Every 50 hours of work you should check the air load inside and if necessary reset pressure by means of a pump.

In the event of excessive pulsations or vibrations, you should certainly check the pulsation dampener, as the purpose of this instrument is to reduce pulsations. Every 50 hours of work you should check the air load inside and if necessary reset pressure by means of a pump.

Excessive noise associated with oil level drops

If the pump starts becoming noisy, check the oil level immediately, if it has decreased it means that the suction line is clogged.

If the pump starts becoming noisy, check the oil level immediately, if it has decreased it means that the suction line is clogged.

Just inspect the suction line (especially the filter) and remove any obstruction.

Excessive oil consumption

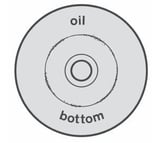

The diaphragms separate the pumping chamber from the transmission, preventing the pumped fluid from coming into contact with the mechanical parts and the oil; when the diaphragm breaks, the fluid filters in the oil making it milky.

At this point it is important to replace all diaphragms and oil to avoid major damage.

Let's now consider the damage that can occur to the diaphragms: in case of breakage of a diaphragm it is important to identify the cause and act to prevent its recurrence.

Two cuts at the suction and discharge valves

- As usual, the first thing to do is to check if the suction line is clogged and clean the filter.

- One of the most common causes is cavitation, vapor bubbles form inside the fluid which implode and ruin the diaphragm. To avoid cavitation there are several useful tips, first of all you should not suck water from excessive depths (maximum 4 meters).

- If the liquid is too thick, use a water-based liquid

- Excessive speed may also damage the diaphragms, it is good practice to keep below 550 RPM

- Always check that the suction valve is closed correctly and that the liner holes are positioned correctly.

- In addition, the diaphragm may also be affected by chemical aggression, always check the compatibility between the diaphragm and the chemical product used.

Breakage close to the inner diameter and lacerations

This is a breakage due to wear, when the diaphragm is used beyond the permitted time (300 hours) the retention disc causes a friction and then lacerations.

This is a breakage due to wear, when the diaphragm is used beyond the permitted time (300 hours) the retention disc causes a friction and then lacerations.

It is good practice to change the diaphragms every 300 hours or at the beginning of every season (the shorter of the two).

Semi-circular sharp cut

This cut is produced by the presence of air in the oil bath under the diaphragm. The air was probably not purged when assembling or repairing, and the diaphragm must now be replaced, taking care to purge the air from the pump.

This cut is produced by the presence of air in the oil bath under the diaphragm. The air was probably not purged when assembling or repairing, and the diaphragm must now be replaced, taking care to purge the air from the pump.

Circular cut, corresponding to the piston diameter in the lower part of the diaphragm

- Lack of oil between piston and liner, to be filled up

- Excessive suction pressure, check that the pump is not supplied by a positive pressure water mains (if this is the case, disconnect)

- Pump speed too low, increase RPM according to the instruction manual

- Incorrect position of the liner holes

- Delivery valve open

Strong laceration at the retention disc, swelling, decreased hardness, increased outer diameter, increased thickness

In this case the deformation is caused by chemical incompatibility between diaphragm and chemical product.