Diaphragm pumps are very commonly used tools, so much so that people often do not even ask what features distinguish them and how they work.

In this article, however, we will clarify some of the main doubts and explain the crucial principles of operation of these efficient devices.

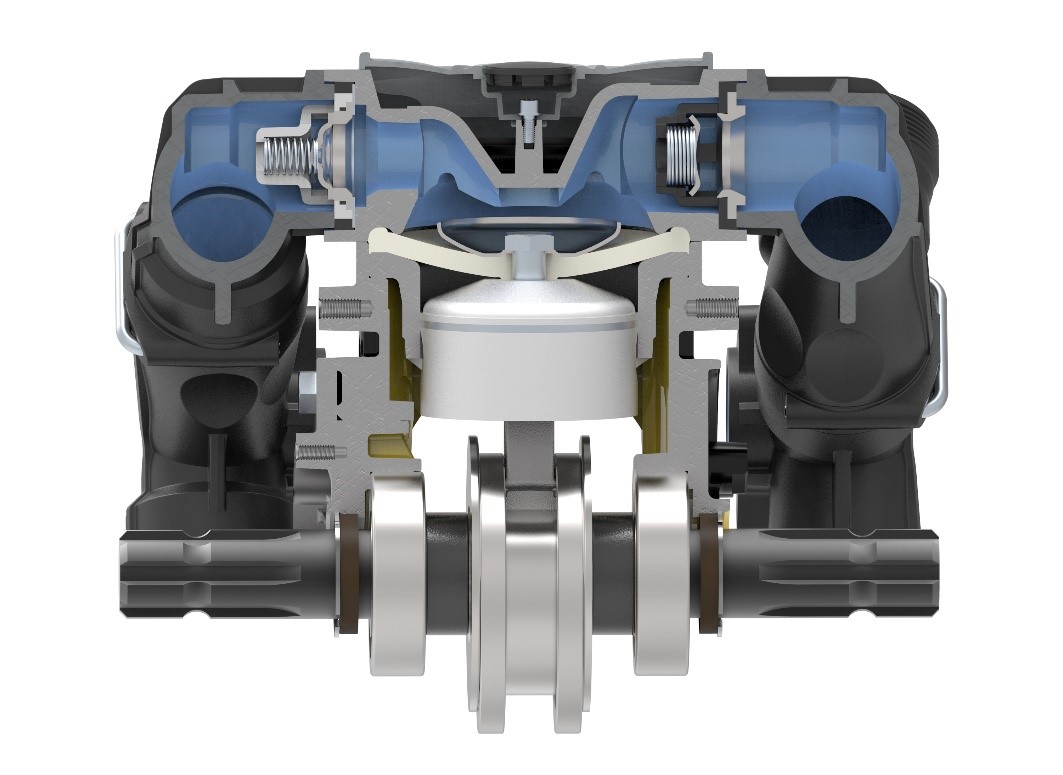

DIAPHRAGM PUMP

A diaphragm pumps is a reciprocating positive displacement pump used to lift a liquid from a lower to a higher point. What distinguishes it from other types of pumps is, precisely, the diaphragm: an elastic element, mounted on the piston of the pump, the purpose of which is to separate the mechanical components from the processed liquid circuit, keeping the pumping chamber well separated from the transmission and preventing the fluid from coming into contact with the mechanical parts and the oil, thus eliminating the cause of serious damage to the pump itself at the origin.

READ: DIAPHRAGM PUMPS, WHAT THEY ARE AND HOW THEY WORK

DIAPHRAGM PUMPS IN AGRICULTURE

These pumps are used in agriculture as components of sprayers or atomizers. They are, therefore, used for weed control and spraying treatments to protect orchards, vineyards and olive groves from pests.

Their widespread use in the agricultural sector is dictated by the main advantages offered by diaphragm pumps, such as excellent priming and self-priming, good dry running, mechanical resistance and resistance to chemical substances: all excellent solutions for situations and elements that are particularly recurrent in agriculture.

READ: EVERYTHING YOU NEED TO KNOW ABOUT DIAPHRAGM PUMPS

After this brief general recap, let’s now go on to dispel the most common doubts about diaphragm pumps.

CAN THE DIAPHRAGM PUMP HANDLE SOLIDS?

Thanks to their diaphragm, these pumps are the only ones that, since their internal components are not in direct contact with the processed material, can pump even liquids that are not perfectly filtered and containing solid residues such as sand, crushed stone and crystals.

Diaphragm pumps substantially provide good mechanical resistance and resistance to chemical substances; therefore, as long as they are constantly served by compressed air, they can safely pump even sewage, sludge, abrasive sediments and water-based substances mixed with acids and solvents.

IS IT POSSIBLE TO RUN A DIAPHRAGM PUMP WITHOUT WATER?

Diaphragm pumps can withstand reasonable periods of dry running without being adversely affected, thanks to a lubricated drive mechanism. For example, in case of a break in the intake line, they operate in self-priming mode. The excellent priming and self-priming function inherent in these tools is due to their ability to create a good vacuum on the intake line.

In addition, unlike centrifugal pumps, diaphragm pumps can operate without filling the intake hose, thus being able to suck in the air contained in the intake hose during the start-up phase and remove it through the delivery line (self-priming). After removing all air, the pump primes and operates normally.

Moreover, compared with centrifugal pumps, these types of pumps are more resistant to overheating and seizure.

READ: 3 MAJOR ADVANTAGES OF USING A DIAPHRAGM PUMP AS AN AGRICULTURAL PUMP

CAN DIAPHRAGM PUMPS RUN CONTINUOUSLY?

The diaphragm of diaphragm pumps moves permanently, so these pumps can operate continuously.

In this way, the pressure generated is kept constant and does not fluctuate, so that the fluid is pumped evenly and without pulsation, unlike other types of pumps that stop their operation once the desired pressure is reached.

CAN THE DIAPHRAGM PUMP FLOW BACK?

We have already seen how what mainly distinguishes diaphragm pumps from other types of reciprocating positive displacement pumps is the flexible element - the diaphragm - that separates the pumped liquid from the moving mechanical components, preventing any contact between these and the oil.

This membrane is also very effective as a barrier that prevents backflow. An additional element that makes diaphragm pumps effective and highly efficient tools.

READ: THE COMPONENTS OF THE DIAPHRAGM PUMPS

DISCOVER COMET’S RANGE OF DIAPHRAGM PUMPS FOR AGRICULTURE