Among the new products Comet presented at the latest Eima edition are the BPX 25 low-pressure spraying pumps. Let’s go into the details of these models.

In this article, we will find out what low-pressure spraying pumps are, what features differentiate them from other pumps and what are some of its special fields of application, in addition to crop spraying.

Spraying pumps

Spraying pumps are included into the category of diaphragm pumps, which are positive-displacement pumps that take advantage of alternating changes in the volume of a chamber (expansion and contraction) to pump liquids through the production of pressure imbalances.

The main advantages offered by these tools are:

- Excellent priming and self-priming

- Good dry running

- High mechanical-chemical resistance of components

Due to these special features, this type of pump is used in agriculture for spraying and performing specific treatments on cereals, vegetables, orchards, vineyards and olive groves.

Low-pressure pumps

The pressure attainable with a positive-displacement pump has no theoretical limits, since it is only limited by the structural strength of its components and its constructional engineering. However, higher or lower pressure produces different results that affect the use for which the pump itself is designed.

READ: DIAPHRAGM PUMPS:WHAT THEY ARE AND HOW THEY WORK

Along with flow rate and power, pressure is one of the key characteristics of a spraying pump.

- Lower pressures, in fact, reduce the velocity of the liquid to be sprayed and increase its average droplet size and spraying angle.

- Higher pressures, on the other hand, reduce its average droplet size and spraying angle.

Low-pressure pumps, therefore, are particularly suitable for weed control and crop protection, especially for corn, wheat, rice and cereals in general: operations for which a maximum pressure of 20bar/290psi is employed.

BPX 25 pumps

Current times have brought new issues into the agriculture scenario, such as environmental sustainability and reduced energy consumption. In addition, new application areas have arisen, such as organic farming.

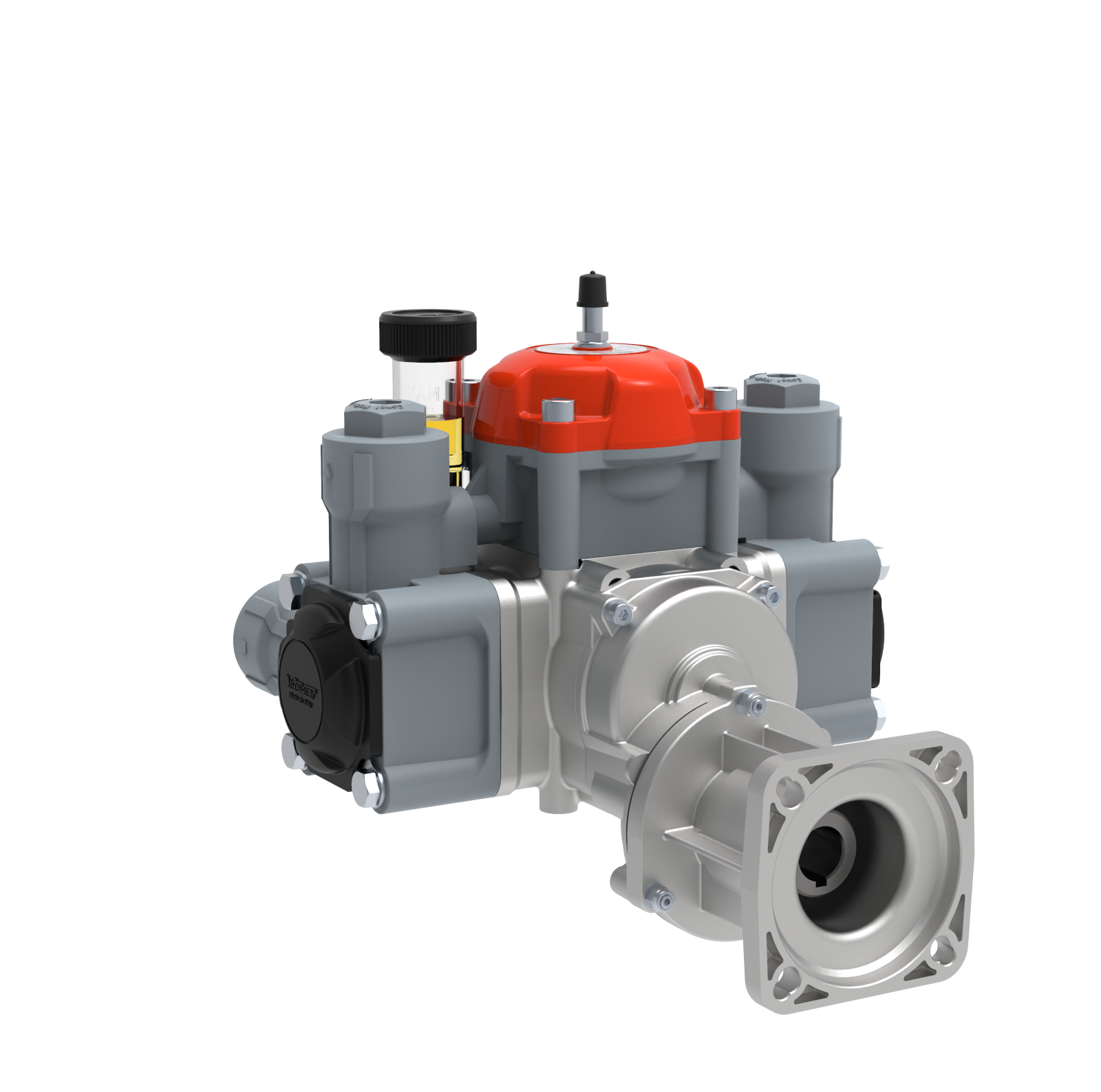

To respond promptly to these challenges, Comet has developed the new BPX25, a positive-displacement piston/diaghragm pump with all-plastic wet-parts for maximum resistance to abrasion and corrosion, an unlimited range of power drives, combined with maximum ease of maintenance, thanks to new external manifolds and valves, which can now be inspected with a standard hex or Allen wrench.

LEARN MORE: COMET’S NEW RANGE OF SPRAYING PUMPS

The BPX 25 main features include:

- Maximum pressure of 15 bar

- Max flow rate of 25 l/1’ @ 540 RPM

The main benefits of this innovative pump are:

- Easy topping up with oil, thanks to the external tank.

- Multiple drive solutions: PTO, hydraulic, stroke, electric, etc.

BPX 25 pumps are particularly suitable in crop protection (including organic crops) and seed inoculation.

The special applications of BPX 25 pumps

Diaphragm pumps are not only used for the protection of crops in their growth phase. The unequalled resistance to chemical attack and mechanical abrasion, in fact, allows extreme versatility for use in other sectors such as:

- Application of soil inoculants

- De-icing

- Removal of moss, algae, etc.

- Sanitization of food facilities

- Dock cleaning in the fishing industry

- Treatment of water contaminated with fuels

In this context, Comet BXP 25 pumps are particularly suitable for special uses such as:

- In-furrow injection

- De-icing

- Soft wash

- Disinfection

- Anti-pollution

What gives BPX 25 pumps their extreme versatility is, first and foremost, the multiple drive options:

- Hydraulic motor

- Electric motor

- Stroke engine

- Battery-powered motor (for some models)

Finally, unparalleled chemical resistance distinguishes Comet BPX 25 pumps, thanks to the combination of the following materials that give the pump unsurpassed service life:

- Polypropylene/nylon heads and manifolds

- Valves with moving parts made of AISI316 stainless steel

- Diaphragms: Viton/Desmopan/NBR