In recent years we have witnessed a tendency towards the oversizing of the atomizers used in the Mediterranean basin, consequently also the technical characteristics of the diaphragm pumps to be mounted on these machines have evolved.

In recent years, the size of sprayers has grown significantly, both in terms of tank capacity and increase in sprayed volumes (l/h).

This has been possible thanks to the use of latest generation turbines which are decidedly larger than in the recent past and have a very high power requirement (kW - HP).

This tendency to oversize atomizers has affected the entire Mediterranean basin, from the boundless olive plantations of Jaén in Andalusia, to the citrus groves of Valencia, passing through the vineyards of Trentino and Tuscany, as far as the olive groves of Kalamata in Greece.

The explanation for this development is linked to the average increase in plots of land and the growing number of contractors in the plant protection treatment sector. European regulations require special certifications (the so-called “license”) to be able to carry out treatments on a large scale, so farmers increasingly tend to contract out spraying to professionals, equipped with the latest generation machines, larger in size and extremely high performance.

Read also: HOW TO CHOOSE THE HIGH PRESSURE DIAPHRAGM PUMP BEST SUITED TO YOUR AIR-BLAST SPRAYER

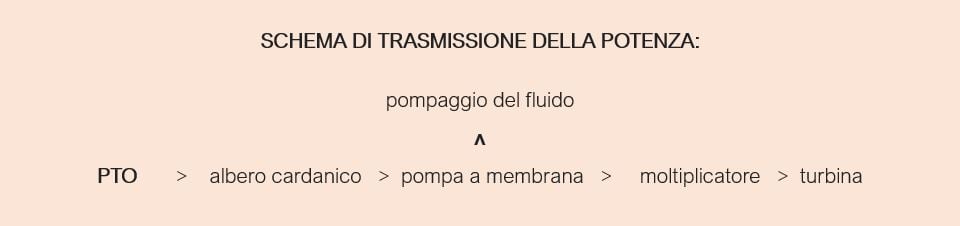

The impact of a large mist sprayer on the diaphragm pump is not secondary, since the latter receives energy from the tractor's power take-off (via the cardan shaft) and transfers it to the turbine (via multiplier).

The indestructible Comet High-Pressure brass pumps

The oversizing of the turbines means the pumps undergo never previously achieved mechanical stresses.

Thanks to constant monitoring of the market with "boots on the field" visits, collaboration with manufacturers and end users and efficient CRM analysis, Comet has developed a range of pumps specifically for these applications.

The new IDS-HD line represents Comet's innovative solution for latest-generation sprayers, whose technological content perfectly meets the needs of the most demanding professional users.

These pumps are equipped with:

- oversized support feet, so that they can easily withstand the thrusts generated by the cardan shaft.*

- 8 made-in-Germany ball bearings (Comet exclusivity) so that the internal drive shaft has maximum absorption capacity of the axial and radial thrusts.

And like any other IDS pump, the HD line offers:

- wet parts (parts in contact with product) made of brass, which ensure utmost resistance to abrasion and corrosion,

- external manifolds for immediate access to the valves and for quick and easy maintenance.

- optimum bore/stroke ratio to minimize diaphragm stress and ensure proverbial longevity to all consumable parts (valves and diaphragms themselves).

With the IDS-HD line, Comet maintains its role as the undisputed world leader in the sprayer pump sector and further enhances the reputation for excellence of its top-of-the-range products.

_____

* Comet recommends, in any case, paying the utmost attention to the selection of the cardan shaft according to the agricultural machine and to always opt for a CONSTANT VELOCITY CARDAN shaft.