The plant protection treatment against parasites and pathologies in canopy orchards, such as vineyards, cherries, apples, pears, plums and olives, is generally carried out by means of an agricultural atomizer that sprays the anti-parasite/water mixture and directs it to the crop to be treated.

Spraying is a very delicate treatment mainly because of the drift phenomenon, i.e. the amount of product that does not affect the plant but is dispersed in the environment.

The drift phenomenon

Drift originates essentially from the need to bring the phytoiatric mixture on the apical part of the plants by spraying these from the bottom upwards. This way, inevitably, a greater or lesser quantity of liquid goes beyond the top of the plants and is dispersed in the air.

The problem is really evident in vineyard or orchard treatments, where the amount of liquid retained by the plants rarely reaches 50%, while it often happens that only 15-30% of the amount distributed reaches the crop.

This event is particularly serious when it’s close to other crops or, even worse, close to homes.

The formation of drift depends on the emission by the machines of a cloud of very fine droplets which, once released into the atmosphere, due to their limited rate of fall, are subject to being carried by the wind at distances which can reach hundreds of meters away from the emission point.

This implies the need to avoid the production of too fine droplets, but without exceeding in the opposite direction with too big droplets because, the volume being equal, larger droplets are less easily carried by the wind, but they cover a smaller surface.

The choice will therefore have to take into account these contrasting trends, thus adopting a compromise solution that generally selects nozzles for medium-sized drops at reduced pressures.

A correct treatment allows improving the deposit of plant protection product on the plants and reducing its drift.

How to choose the most suitable diaphragm pump

The choice of the diaphragm pump to be installed on a sprayer directly influences the pressure to which the plant protection mixture is subjected and therefore, together with the nozzles, is directly responsible for the spray pressure and volume.

To choose a diaphragm pump correctly, two main variables must always be taken into account: flow rate and pressure.

Flow rate

Flow rate is the volume of fluid flowing through the pump per unit of time. Two main factors must be considered when determining the total flow rate required by a diaphragm pump:

- application requirement

- agitation requirement

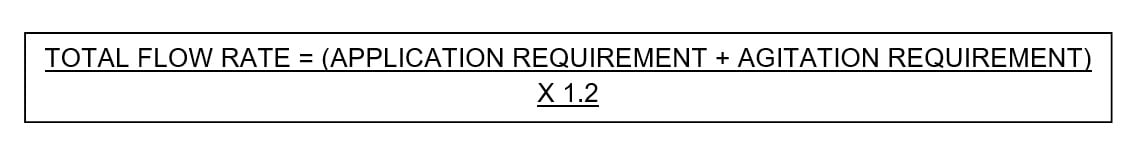

The flow rate is the sum of these two values: application requirement and agitation requirement multiplied by 1.2 (safety margin)

The application requirement can be found thanks to a simple formula that varies depending on the type of treatment, the figure shows the one relating to orchards and vineyards.

It will always be necessary to add, to the result obtained, the 20-25% of additional margin of tolerance to compensate for the drop in flow rate generated by any hydraulic circuit.

The tank agitation requirement is calculated using two other formulas:

The tank agitation requirement is calculated using two other formulas:

- Liquid chemicals

tank volume in liters x 0.05 = agitation requirement (l/min) - Soluble powders

Deposit volume in liters x 0.125 = agitation requirement (l/min)

Pressure

Pressure is the force exerted orthogonally on a surface by a solid or by a fluid in contact with the same.

The pressure requirements of a pump depend on the maximum pressure of the nozzle that is selected depending on the specific application.

Normally, high pressure diaphragm pumps are used to treat orchards and vineyards:

Comet pumps for atomizers

Thanks to these calculations it is possible to exactly identify the most suitable diaphragm pump to be installed on each atomizer.

The range of Comet Pumps starts from the MC Series, suitable for small spraying treatments such as the protection of crops in gardens, greenhouses, lawns and for the dispensing of water-soluble paints and detergents.

General characteristics:

- Configuration: 2 diaphragms

- Pressure: up to 25 bar (362 psi)

- Flow rate: up to 23 l/min (6.1 USgpm)

- Manifolds: 61 internal

- Parts in contact with the liquid: anodized aluminum, plasticized aluminum, polyamide and polypropylene according to the selected model.

For medium and large-sized atomizers, we move on to the APS (Special High Pressure) Series, a worldwide reference for atomizer pumps.

General characteristics:

- Configuration: 3 to 5 diaphragms

- Pressure: up to 50 bar (725 psi)

- Flow rate: up to 169 l/min (44.6 US gpm)

- Parts in contact with the liquid: anodized aluminum

- Manifolds: internal

- Applications: medium and large-sized atomizers.

This is a low-maintenance pump, thanks to its optimum stroke/bore ratio which is able to minimize the stress on the diaphragms; it has an unparalleled priming capacity and a compact design to adapt to the lack of space available on orchard sprayers.

For those working in the most extreme conditions, such as vineyards and orchards in certain geographical areas (dusty environments, tropical temperatures, uneven tracks, etc..), or using particularly aggressive products, Comet has designed a pump that can adapt to the harshest operating conditions: the IDS Series is the top of the range.

General characteristics:

- Configuration: 3 to 6 diaphragms

- Pressure: up to 50 bar (725 psi)

- Flow rate: up to 259 l/min (68.4 US gpm)

- Parts in contact with the liquid: brass

- Manifolds: 48 external

- Applications: medium and large-sized atomizers.

All parts in contact with the liquid are made of brass, allowing maximum resistance to abrasion, the perfect choice for those who need a really indestructible pump. The manifolds are external to facilitate maintenance.